Alternative to LST (low surface temperature) Radiators

At a Glance:

- Improved infection control – simply wipe clean when mopping the floors

- No deep clean teams – no heavy covers to remove and no thoroughfare obstructions

- Improved safety – no hard edges or bulky covers, reducing fall and trip hazards

- Increased useable space – all walls free, enabling versatile room layouts

- Simple to install – new build or retrofit

- Reduced running costs – not only cleaning and maintenance, but energy saving too

- Anti-ligature – completely sealed to protect those who might self harm

- All around room heating – feels like underfloor but without the slow response

- Can be colour coordinated to match the room or to provide a visual marker

- No convection currents carrying dust – ideal for asthma and other respiratory illnesses

Infection Control and Health & Safety are two major concerns in the Health & Care Service; ThermaSkirt addresses these 2 main concerns far better than the current norm of LST radiators.

Consider:

- At any one time 15% of patients have an HAI

- Patients contracting a HAI spend nearly 3 times longer in hospital

- The estimated additional cost to the NHS is more than £1 Billion each year

- There are almost 300,000 HAI’s each year in England

- Nearly 9,000 deaths attributed to MRSA and other “Superbugs” in 2007

- Cleaning wards in 2004 cost Hospital Trusts over £522 Million

(Source: House of Commons Public Accounts

Committee – Reducing Healthcare Associated

Infection in Hospitals in England – November 2009)

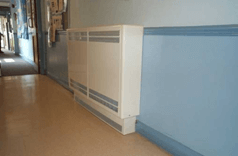

Until recently, LST (low surface temperature) radiators have been widely used in Healthcare, as they provide a simple heating system and are a well understood technology. With the recent drive to eradicate HAI’s (healthcare acquired infections) they have now been de-selected on any new NHS projects, as they are practically impossible to keep clean.

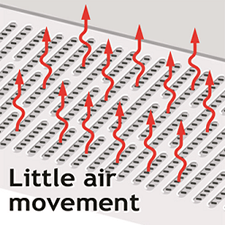

It has been found that the convection currents they create draw in the microbiological infections from the floors, and into the radiator covers where they may hibernate in the dust and detritus already inside. At some point, when the radiators are turned on it can be shown that these same infections such as C.Difficile and MRSA are then expelled in the warm air from the radiators, and carried around the heated space, leading to their spread.

With the recent rise in the awareness of so called ‘Superbugs’ such as MRSA and E.coli, C.Diff & MRSA, the problem of Healthcare Acquired Infection (HAI) has never been more acute.

The risk of bacteria cross-contamination and contracting an infection is particularly high in the healthcare sector, where there are a large number of people with reduced immunity levels, in close proximity and an abundance of bacteria and infections.

Obvious ways of passing on infection are direct contact with contaminated surfaces or via proximity and/or airborne communication.

The Association of Healthcare Cleaning Professionals (AHCP), recommend that radiators & covers should be thoroughly cleaned and disinfected at least once a week, which led to the development of LST radiator covers that drop down and radiators that hinged in order to effect a deep clean.

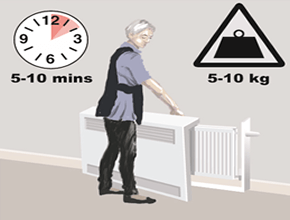

Practically though, this was impossible to achieve, as an average city hospital has around 800 radiators and the weight and size of the covers and water-filled radiators meant that only a well-trained army of physically fit cleaners could ever hope to meet that target.

Typical weights & sizes of LST Radiators when filled

| Radiator Type | Double Panel | 22 | 22 | 22 | 22 | 22 | 22 |

|---|---|---|---|---|---|---|---|

| Radiator Height (Usual sizes underlined) | 300mm | 400mm | 500mm | 600mm | 700mm | 900mm | |

| Dry Kg Per Metre |

18.20 | 24.63 | 31.07 | 37.50 | 43.67 | 56.00 | |

| 300 | 5.46 | 7.39 | 9.32 | 11.25 | 13.10 | 16.80 | |

| 400 | 7.28 | 9.85 | 12.43 | 15.00 | 17.47 | 22.40 | |

| 500 | 9.10 | 12.32 | 15.54 | 18.75 | 21.84 | 28.00 | |

| 600 | 10.92 | 14.78 | 18.64 | 22.50 | 26.20 | 33.60 | |

| 700 | 12.74 | 17.24 | 21.75 | 26.25 | 30.57 | 39.20 | |

| 800 | 14.56 | 19.70 | 24.86 | 30.00 | 34.94 | 44.80 | |

| 900 | 16.38 | 22.17 | 27.96 | 33.75 | 39.30 | 50.40 | |

| 1000 | 18.20 | 24.63 | 31.07 | 37.50 | 43.67 | 56.00 | |

| 1100 | 20.02 | 27.09 | 34.18 | 41.25 | 48.04 | 61.60 | |

| Length (Usual sizes underlined) | 1200 | 21.84 | 29.56 | 37.28 | 45.00 Kg | 52.40 | 67.20 |

| 1300 | 23.66 | 32.02 | 40.39 | 48.75 Kg | 56.77 | 72.80 | |

| 1400 | 25.48 | 34.48 | 43.50 | 52.50 Kg | 61.14 | 78.40 | |

| 1500 | 27.30 | 36.95 | 46.61 | 56.25 Kg | 65.51 | 84.00 | |

| 1600 | 29.12 | 39.41 | 49.71 | 60.00 Kg | 69.87 | 89.60 | |

| 1800 | 32.76 | 44.33 | 55.93 | 67.50 Kg | 78.61 | 100.80 | |

| 2000 | 36.40 | 49.26 | 62.14 | 75.00 | 87.34 | 112.00 | |

| 2200 | 40.04 | 54.19 | 68.35 | 82.50 | 96.07 | 123.20 | |

| 2400 | 43.68 | 59.11 | 74.57 | 90.00 | 104.81 | 134.40 | |

| 2800 | 50.96 | 68.96 | 87.00 | 105.00 | 122.28 | 156.80 | |

| 3000 | 54.60 | 73.89 | 93.21 | 112.50 | 131.01 | 168.00 |

* Caution

* 2 person Lift

* HSE Guidlines Requires Mechanical Lifting Equipment

Impacts, Trips & Falls

According to RoSPA, there are on average of 29,000 accidents involving radiators every year (source: HaSS & LaSS Statistics, 2001/2). Of these, more than 90% are impact injuries resulting from trips or falls onto them.

Despite the assertion that radiator covers make them ‘safer’ they in fact do far less to address the major cause of injury which is the young or old falling onto them.

Despite the laudable adoption of rounded edges and concealed controls, the fact is that they still represent a 6”~ 8” protrusion of a hard surface that will cause significant injury if fallen onto. Unwary or uncontrollable patients could still collide into the side of them if moving at speed, causing serious injury, and of course they still provide an obstruction for trolleys and gurneys to negotiate.

| Falls, Trips, Impacts | 25,936 | 86.66% |

| Grab injury burns to hands & arms | 1,847 | 6.10% |

| Burns to other parts of body | 583 | 1.90% |

| Other Causes | 1,543 | 5.16% |

| Total Radiator Accidents | 29,909 | 99.82% |

Risk of Strangulation (Ligature)

In 2005, more than 1500 persons committed suicide by hanging or self strangulation. As in most of these cases, death is caused without the victim being suspended, the risk of a ligature fixing must be removed. There should be no exposed pipes or valves that can enable the person in the care of the hospital or state to fix a ligature (a twisted bedsheet or item of clothing) to and take their own life.

In the case of LST radiators, there are a number of potential ligature points that need protecting by lockable covers or fixed with security screws. This inevitably requires cleaning staff to be issued with the appropriate keys and/or release tools.

Not with standing the logistical issues of the distribution of these keys & tools, there is also the risk of the theft or misappropriation of said keys and their misuse, and the probability of more than 1 key code/type being required to prevent this.

The man hours required to maintain & control the issue of these keys cannot be underestimated.

ThermaSkirt More than Pays for Itself

Assuming 800 radiators per Hospital, and average of 2 radiators per room/zone (400 rooms/zones)

| Traditional LST Rads & Covers Fixed Covers |

New Style Demountable LST Rads & Covers (Manufacturers Claim) |

ThermaSkirt Assumes 400 rooms/zones (source; Trafford General) |

| 2 Persons involving Estates (with tools and equipment) | 1 person task (with appropriate training and ability to lift >30Kg. with keys and/or release tools) | 1 person task (regular cleaning staff with mop & bucket) |

| 30 minutes to remove casing | 5 minutes to remove and replace cover | N/A |

| 10~15minutes to clean wall, cover (both sides) and radiator (outer panels only) | 10 minutes to clean wall, cover (both sides) and radiator (outer panels only) | 120 seconds (Assumes a perimeter of 20m (room area of 25m2) = 3m2 of ThermaSkirt (1.5m2 per minute of mopping) |

| 8 hour working day = 15 LST per day | 8 hour working day = 32 LST per day | 8 hour day = 3,200m2 of Thermaskirt = 1,060 systems per day |

| 53 days to clean every radiator | 25 days to clean every radiator | < 1 day to clean every system |

| Cleaning Team of 100 persons required (radiators only) | Cleaning Team of 32 persons required (radiators only) | 1 cleaning person required (ThermaSkirt Cleaning Only) |

| Annual budget of > £1.7m (Radiator Cleaning Only, every day) |

Annual budget of > £550,000 (Radiator Cleaning Only, every day) |

Annual budget of £16,000 (ThermaSkirt Cleaning Only, every day) |

Annual Saving: Over £1,600,000

Running Costs: ThermaSkirt Vs LST Radiators

ThermaSkirt® has been independently tested by BSRIA to be at least 13% more efficient than a standard radiator system. This is because the heat is distributed around the entire perimeter of the room, and the larger surface area creates an even all round thermal environment. This more efficient heat distribution means that it can be run at lower temperatures, saving fuel costs and overall running cost of the heating system.

If a boiler is turned down by 1.25°C it can reduce its carbon emissions by 5%, and with CO2 footprint reduction a key improvement target throughout most NHS Trusts ThermaSkirt® provides a significant step forward, as it can run with a flow temperature of 45&dge;C and maintain a mean room temperature of 21°C.

Radiators create convection currents, and rely on these convection currents to circulate the warm air around the room. The speed of the convection currents is directly proportional to the temperature of the radiator and the flow rate of air passing across it. This means that when the temperature is lower, then air flow & convection speed is lower. This does not allow enough momentum energy at low temperatures & air flow rates to carry the warmed air across the room. So the Low Surface Temperature Oversized Radiators, although overcoming the risk of scalding, seriously compromises the ability to heat a room. The covers ensure that flow temperatures have to be increased to 80°C+ to compensate.

- Radiator Guards & grilles restrict air movement – a radiators only source of heat distribution

- Ligature grilles reduces convection currents by 80%

- Heating system temperatures often raised to 85°C to compensate – reducing efficiencies still further

- Radiator manufacturers neither provide nor recommends radiator covers as they severely inhibit performance

- Heat build up inside covers often pushes surface temp to well over recommended limit – obviating their primary purpose