Welfare of Staff

- EasyClean does not cause ‘dead leg’ syndrome synonymous with standing on heated floors

- EasyClean does not cause ‘hot head’ issues, as often caused by overhead radiant panels

- Access to pipe work is simple and ‘above ground’ requiring no access platforms or ladders for overhead working

- EasyClean usually operates on low temperature water and so there is no risk of scalding from water, pipes or surfaces

- Walls clear of obstructions and impact hazards such as radiators and covers

- Overheating and under heating are eliminated to create a comfortable working environment

In order to provide the best possible care for persons in hospitals, care home and assisted living ,it is imperative that the staff providing the care are well looked after as well.

The Royal College of Nursing has recognised the potential for considerable discomfort and circulatory problems in staff who stand or walk for hours on heated floors. “Dead leg” syndrome is often used to describe the feeling of tiredness and aching in the feet and lower legs caused by swelling of the feet due to continuous heating.

As a result, staff performance and efficiency can be compromised, and even days lost to sickness.

Similarly, overhead radiant panels project heat from the ceiling down and often operate at high surface temperatures to overcome the natural tendency of heat to rise. As a result, the projected infra red rays created, when beaming directly on top of the head, can cause discomfort, irritability and in extreme cases, nausea. Overhead radiant panels should be at least 2.7m off the floor, and not located directly over places where persons may be immobile for long periods. This includes work stations, desks, and of course beds. This limits the freedom and flexibility of room layouts, even if the facilities operators remember to consider such an imposition.

The location of EasyClean at ground level also makes any maintenance or repairs straightforward with no need for access platforms or fall arrest equipment to service heating systems in the ceilings.

LST radiators and covers present a considerable hazard in the event of a fall or a trip. Despite often having a rounded top edge, collision onto the side, or a fall onto the top of a sheet steel cover can prove painful or disabling.

The latest RoSPA Hass & LaSS reports into radiator safety highlights that impact trips and falls make up more than 90% of the injuries associated with radiators.

(ROSPA TABLE OF ACCIDENTS)

| Radiator Related Injuries | ||

| Falls, Trips, Impacts | 25,936 | 86.66% |

| Grab injury burns to hands & arms* | 1,847 | 6.10% |

| Burns to other part of body | 583 | 1.90% |

| Other Causes | 1,543 | 5.16% |

| Total Radiator Accidents | 29,909 | 99.82% |

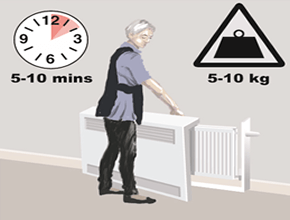

LST Radiators and their protective covers can be heavy & difficult to move and lift

(From the Unison & GMB website)

There are no legally binding weight limits. However Regulation 4(1) of the Manual Handling Operations Regulations 1992 sets safety standards for manual handling.

The employer must:

- avoid the need for manual handling as far as is reasonably practicable;

- where that is not possible, assess the risk of injury to employees; and

- reduce the risk of injury from manual handling as far as is reasonably practicable

Avoiding the Need for Manual Handling

The employer must try to eliminate the need for manual lifting. If this is not possible the employer should consider using mechanical lifting, (for example by using a mechanical device).

Assessing the Risk of Injuries to Employees

Under the 1992 Regulations the employer must carry out a risk assessment. This must take into account the tasks; the loads involved; the working environment; an individual’s capacity and health; and whether movement is hindered by personal protective equipment. (Such as safety shoes with steel toe caps)

Other Industry Guidelines on Safe Working Loads (swl)

In the building industry, which had an alarming rate of injuries, great strides have been taking in reducing the numbers of employees injured every year. In part this is the stricter enforcement of PPE (personal protective equipment) but mainly because of the emphasis on swl. Packs of sand, cement, plaster and aggregate have all seen their standard pack sizes fall to 20Kg or less. The industry recognises that handling items over this weight, repetitively, leads to a significant increase in back injuries and other RSI (repetitive strain injuries).

In the radiator industry itself, data from the manufacturers own internal data on mechanical handling makes it quite clear that handling radiators over 25kg requires 2 men, and over 50Kg requires mechanical lifting equipment (such as hoists, jacks or fork lift). As the dry weight of a common radiator size (1200mm x 600mm double panel) is 45Kg alone, it is misleading to suggest that radiators of this size and weight can be handled day in-day out by cleaning personnel single-handed.

Typical weights & sizes of LST Radiators when filled

| Radiator Type | Double Panel | 22 | 22 | 22 | 22 | 22 | 22 |

|---|---|---|---|---|---|---|---|

| Radiator Height (Usual sizes underlined) | 300mm | 400mm | 500mm | 600mm | 700mm | 900mm | |

| Dry Kg Per Metre |

18.20 | 24.63 | 31.07 | 37.50 | 43.67 | 56.00 | |

| 300 | 5.46 | 7.39 | 9.32 | 11.25 | 13.10 | 16.80 | |

| 400 | 7.28 | 9.85 | 12.43 | 15.00 | 17.47 | 22.40 | |

| 500 | 9.10 | 12.32 | 15.54 | 18.75 | 21.84 | 28.00 | |

| 600 | 10.92 | 14.78 | 18.64 | 22.50 | 26.20 | 33.60 | |

| 700 | 12.74 | 17.24 | 21.75 | 26.25 | 30.57 | 39.20 | |

| 800 | 14.56 | 19.70 | 24.86 | 30.00 | 34.94 | 44.80 | |

| 900 | 16.38 | 22.17 | 27.96 | 33.75 | 39.30 | 50.40 | |

| 1000 | 18.20 | 24.63 | 31.07 | 37.50 | 43.67 | 56.00 | |

| 1100 | 20.02 | 27.09 | 34.18 | 41.25 | 48.04 | 61.60 | |

| Length (Usual sizes underlined) | 1200 | 21.84 | 29.56 | 37.28 | 45.00 Kg | 52.40 | 67.20 |

| 1300 | 23.66 | 32.02 | 40.39 | 48.75 Kg | 56.77 | 72.80 | |

| 1400 | 25.48 | 34.48 | 43.50 | 52.50 Kg | 61.14 | 78.40 | |

| 1500 | 27.30 | 36.95 | 46.61 | 56.25 Kg | 65.51 | 84.00 | |

| 1600 | 29.12 | 39.41 | 49.71 | 60.00 Kg | 69.87 | 89.60 | |

| 1800 | 32.76 | 44.33 | 55.93 | 67.50 Kg | 78.61 | 100.80 | |

| 2000 | 36.40 | 49.26 | 62.14 | 75.00 | 87.34 | 112.00 | |

| 2200 | 40.04 | 54.19 | 68.35 | 82.50 | 96.07 | 123.20 | |

| 2400 | 43.68 | 59.11 | 74.57 | 90.00 | 104.81 | 134.40 | |

| 2800 | 50.96 | 68.96 | 87.00 | 105.00 | 122.28 | 156.80 | |

| 3000 | 54.60 | 73.89 | 93.21 | 112.50 | 131.01 | 168.00 |

* Caution

* 2 person Lift

* HSE Guidlines Requires Mechanical Lifting Equipment

Source: Quinn/Barlo Radiators & Kermi GmbH