ThermaCurve has been developed from the highly successful ThermaSkirt product.

ThermaCurve provides a surface mounted aesthetically pleasing, far infrared heater, designed to look like an integral architectural feature.

It combines the heating into a discreet, robust, architectural

feature that can be installed where wall space is practically

non-existent or where traditional panel heaters would

be vulnerable to damage.

These include temporary

accommodation, hotel rooms, student accommodation,

portable buildings or dementia care and assisted living

and many other hard to heat spaces.

Q. Why is ThermaCurve better than a standard panel heater?

A.

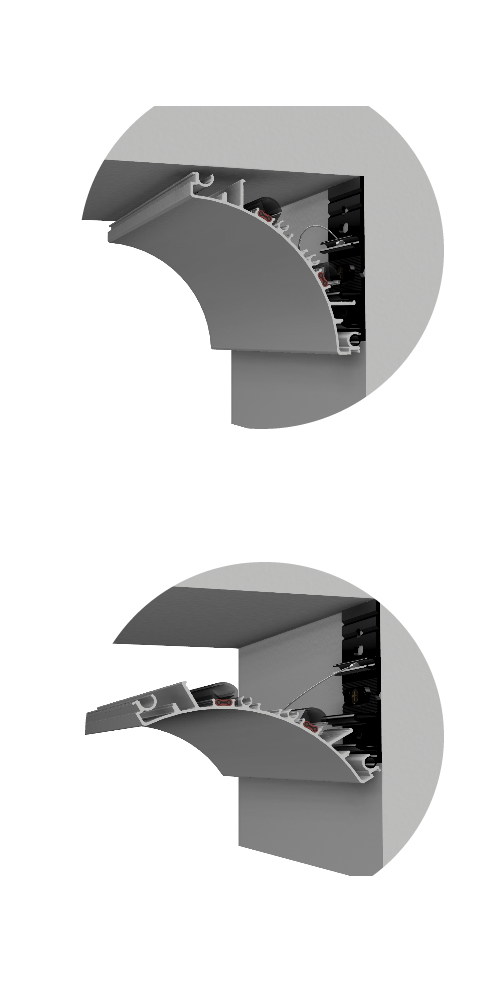

Where wall space is at a premium, or where the risk of damage can be reasonably foreseen, ThermaCurve can be mounted at the junction between wall and ceiling, similar to a coving feature and thus completely out of harms way. When mounted vertically in a corner, the grille-free, robust aluminium profile means that there is no opportunity to tamper or for liquids or dirt to penetrate the housing – especially when the unit is sealed to the walls using the unique caulking trim.

If mounted up and out of the way, and with an operating temperature similar to a conventional wet radiator, the risk from a scald or burn is completely eliminated. In addition, conventional panel heaters must include a failsafe thermal fuse to avoid starting fires if covered over; both these concerns are eliminated by ThermaCurves unique Fire Sure™ heating element, and its location away from furnishings and curtains.

Q. Why is ThermaCurve better than underfloor heating?

A.

By placing the heating up and out of the way, or standing vertically in a corner, ThermaCurve takes up no useable floor or wall space and starts to heat the space almost from the moment it is activated; irrespective of the floor covering or furniture.

It is simple to install and retrofit, and in the unlikely event of a fault is easily accessed using typical service engineers’ tools. Being above ground, not only does ThermaCurve respond quickly to heat demand, it also cools quickly which can help to address overheating which is a common concern in modern well insulated buildings using UFH.

Q. Why is ThermaCurve better than overhead radiant panels?

A.

Similarly, with the ceiling void needed for distributed LED lighting (either downlighters or integrated ceiling panels), fire alarms, building control systems and other services including water, finding room to install an overhead panel can be difficult.

Whilst some overhead panels are designed to be integrated into the plaster ceiling, the majority are still surface mounted and thus potentially visually intrusive. Ceiling mounted heaters will also require some additional local strengthening to safely support their weight, ThermaCurve however, can be simply installed using conventional wall plug and screws to the walls, as the lower weight is evenly distributed over a wide area

No Boiler?

No Problem.

Electrical heating is not always suitable for every building. However, it is a perfect solution for smaller, well insulated buildings with low energy requirements – making it a great choice for new homes.

With more and more electrical energy being generated from renewable sources, it can also help to reduce the overall carbon impact of a building.

Once electric heating is installed, as more and more of the grid ‘goes green’ swathes of houses can be automatically upgraded to low carbon heating, without any disturbance or modification.

How does it work?

Manufactured from a highly efficient aluminium polymer,

ThermaCurve is warmed by a unique fire-safe heating element,

secured to the rear of the profile. When energised, almost

immediately ThermaCurve starts to evenly warm the room using

infra-red radiant heat, distributed over a wide area – often the full

length of one wall.

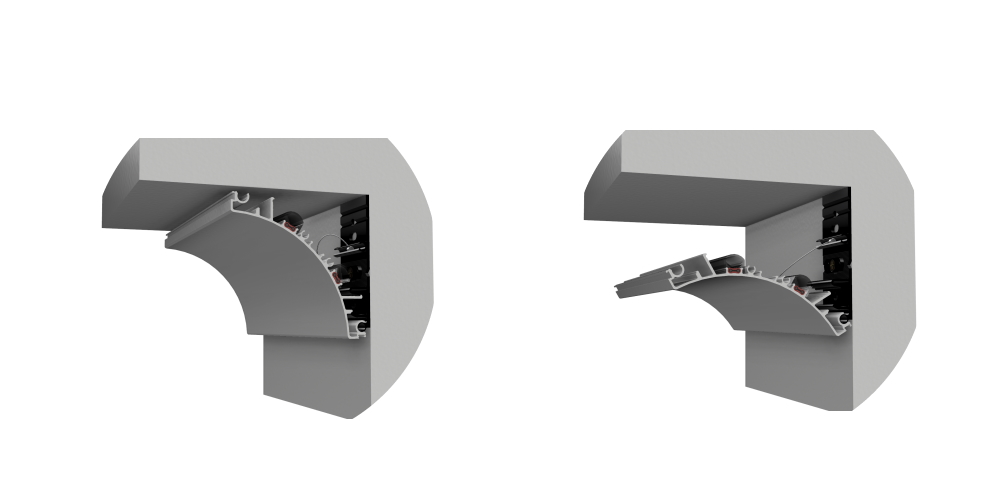

The innovative curved profile creates a broad beam of heat,

projected downwards at all angles between 90~180°, providing

a gentle, even heat that can help to improve comfort levels and

reduce running costs.

How is it installed?

ThermaCurve is manufactured in sections up to 6m, (20’) and so almost any wall can be installed in a single length as the profile is simply cut with conventional power tools. The aluminium profile is also available in a building industry friendly 2.2~2.4m pre-prepared length to adjust from floor to ceiling if vertically mounted in a corner. Cleverly designed adjustable wall brackets allow the profile to be securely fixed to the wall, and permit an initial ‘hinged’ opening function, providing access to the rear of the profile.

Unless pre-installed, the unique fire-safe heating element is then

inserted into the profile and the electrical connection made at one

end. The profile has a clever ‘mirror image’ design, so that it can

be installed in either direction, left to right, top to bottom and vice

versa without having to spin the profile around or reconfigure the

wiring. Once clipped onto the brackets, the profile is then swung

shut, creating a seamless, discreet heating system which can be

colour matched to suit the wall or décor.

The profile has adjustable clip-on covers to hide the electrical

connections and any corner joints.

Energy Efficient

ThermaCurve is considered a radiant infra-red panel heater in the upcoming SAP10 and Future Homes Standard and

thus 100% energy efficient at the point of use and with a ‘1’ for responsiveness.

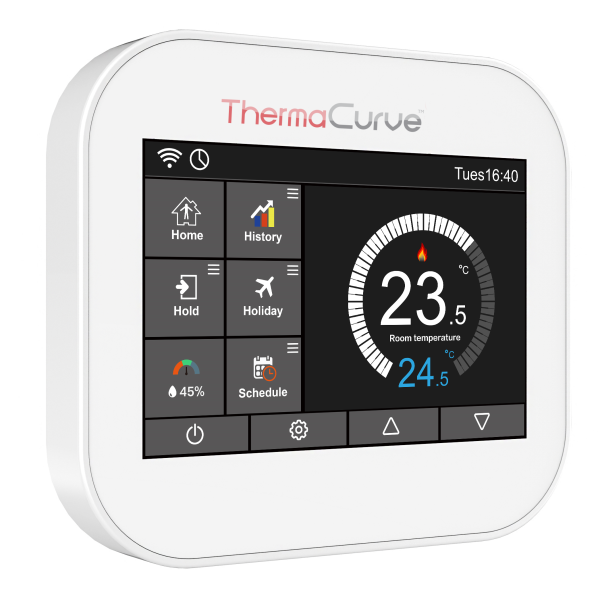

Where preferred, ThermaCurve can be connected via the ingenious

Eco-Start™ PCB controller that can save up to 40% in energy

consumption. The Eco-Start controller initiates in a ½ power mode

for the 1st 5 minutes to ensure that when the room is hovering

around the target temperature, only just enough energy is used to

return the room back up to the desired setting. This contrasts with

most conventional panel heaters that are either ‘Off’ or ‘Full ON’

which often leads to overheating and thus wasted energy. In tests,

when using the Eco-Start PCB, 80% of the programmed operating

times were either in the ‘Off’ or ‘ ½power’ state, whilst maintaining

the desired room temperature (21°C in these particular tests).

By creating an even, convection current-free warm environment,

occupants can feel comfortable at lower set temperatures

compared to conventional panel heaters. This means that the

thermostat can be turned down and according to the Energy

Saving Trust, turning the thermostat down by just 1°C can save up

to 10% of your running costs.

If there is a concern about heat being lost into the ceiling void, then

an Eco-Bubble reflective thermal insulation roll can be provided to

create a U value below 0.25 in the void behind the profile.

Future Proof

With volatile oil prices and uncertain supply, less and less natural gas and more renewable electricity production, heating your home with an electric heating system will future proof your property. With the UK's commitment to reduce its carbon footprint by adopting more renewable energy such as solar, wind and nuclear, it all points towards electricity as the fuel of the future.

Electric heating is 100% efficient and carbon neutral at the point of use, and with gas boilers being phased out on new build from 2025, more and more developers are switching to electric heating with its minimal maintenance, single utility power provider and wide choice of heat emitters.

Any Other Advantages?

Optional decorative trims can be added to the top and bottom edges to create a more architecturally individual and interesting aesthetic.

A matching dummy profile is also available if the profile feature is required to continue onto other walls and not just the heated sections. Bespoke colours and decorative trims are available to suit larger project requirements.