Homeowner's Guide to Gas Boilers

IS YOUR SYSTEM UP TO THE JOB?

So what is a gas boiler?

SIMPLE OR STUPID QUESTION? HERE'S THE 3 MAIN OPTIONS...

Combi/Combination Boiler

The heating and hot water are combined into one as there is no hot water tank. Domestic Hot water is created at the time of need, and if the heating is currently on, it is temporarily turned off whilst hot water is delivered to the point of use. These are the most common boilers fitted over the last 20 years.

Conventional System Boilers

System boilers have a hot water tank (usually in an ‘airing’ cupboard) to

store and deliver hot water to the baths and showers and sinks, and as

such the heating can be run continuously. These are usually found in

larger properties with 2 or more bathrooms.

Often, on older systems the water is supplied to the system from a cold

water storage tank in the loft. As a result the system is typically running

under gravity pressure. This is known as a Traditional Boiler.

CHP Boiler (Combined Heat & Power)

Relatively rare, these use gas energy to not only provide hot water and heating, but also to move a mechanical mechanism that generates electricity as well.

These categories apply to mains gas (or network connected) as well as LPG tank, cylinder stored gas or oil that are used in more rural or remote areas.

Hydrogen H2 Ready boilers.

The Government is actively encouraging boiler manufacturers to make their products Hydrogen ready for 2026. Hydrogen produces no CO2 when burnt, and so is part of their Net Zero strategy for 2050. These boilers will be designed to burn hydrogen rather than natural gas with a few simple part changes provided by a service engineer. Some H2 ready boilers are expected to be launched in 2022

Which one do I have?

HOW TO IDENTIFY YOUR SYSTEM...

If your boiler was installed in the last 20 years & you have

no cylinder in a cupboard, then you almost certainly have a

combi boiler.

If you have a hot water cylinder somewhere in the house,

but no cold water header tank in the loft, then you have a

system boiler.

Combi & System boilers account for 90% of all the gas

central heating systems currently installed in the UK.

IS IT A CONDENSING BOILER?

Since 2005, all gas boilers (Combi & System) have to incorporate Condensing technology and is a requirement to achieve the ‘A’ rating. A condensing boiler captures the heat from the exhaust gases and recycles it to preheat the incoming water, thus reducing the overall energy consumed. In the process, water vapour in the exhaust gases is condensed creating a small amount of water that needs to be drained to waste usually through an outside wall. To identify this, look for a white pipe at the bottom of the boiler, typically 22mm in diameter.

TOP TIP: In a very cold weather snap the greatest cause of boiler call-outs is a frozen condensate waste pipe so check that first if your boiler indicates a fault condition

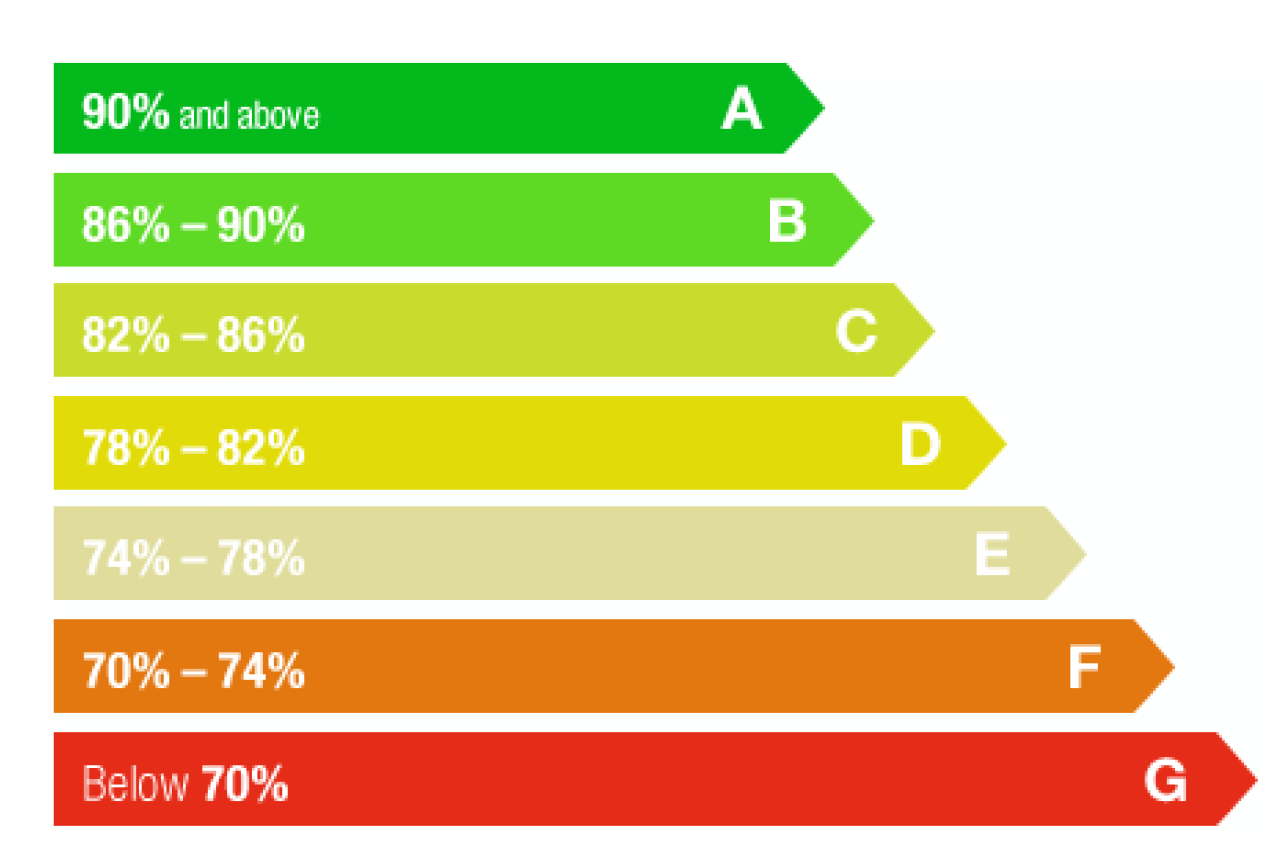

S IT 'A' RATED?

Most domestic appliances have an energy rating based on the efficiency. These rate from F to A with more recently A+ and even A++ ratings being introduced. All boilers from 2015 have to be A rated as a minimum; which is to say 90% energy efficient. A+ & A++ are 92% & 95% efficient respectively. If your boiler does not have an energy rated sticker then chances are your boiler is not A rated and you might want to consider a replacement.

Do I Need to Replace It?

WHAT ARE THE SIGNS THAT IT'S TIME TO RETIRE...

As a rule of thumb, the CIPHE (Chartered Institute of Plumbing & Heating Engineers) recommend that your boiler is replaced every 10 years; but they would, wouldn’t they? Many manufacturers now offer typically 7 and sometimes 10 year warranties on their boilers so a lifespan of 10 years plus is easily achieved.

WHAT ABOUT THE MONEY?

Whilst an A rated boiler can save you around £200 per year compared to a G rated boiler in a 3 bed Semi-detached (source; energy saving trust) a boiler swap can cost between £1,500 & £2,000 so it can therefore take up to 10 years to recoup the cost of replacement if that is the only thing that concerns you.

SHOULD I SERVICE MY BOILER?

If your boiler is less than 20 years old, is reliable and you have it serviced every 2~3 years (every year by law if you are a landlord of a rented property) then there is no financial reason to swap out your boiler. If you have concerns about CO2 emissions, reliability in the winter, or if you are planning to sell your house (an older boiler will reduce the EPC rating of your property) then you might feel it appropriate to replace your boiler with an A or A+ rated appliance.

Can I Reduce the Running Costs?

HOW TO MAKE THE MOST OF WHAT YOU HAVE....

According to the energy saving trust, reducing the thermostat setting by 1°C can save an average of 10% (typically £60~£80 per year). By simply setting your rooms to 20°C rather than 21°C, you can make a big difference.

TURN IT DOWN!!!

If you turn you boiler down to, say, 65°C rather than the more usual 75°C then your boiler will run more efficiently, typically 3% better. This is because condensing boilers (see above) only condense when the water returning from your heating is 58°C or less (to create the cooling effect that causes condensing). If your return temperature is 60°C or more, your boiler won’t be condensing, it won’t be achieving the A efficiency rating and you won’t be maximising your energy savings. By having a lower flow temperature to start with you can practically guarantee that your return temperature will be below 58°C and so will be operating at maximum efficiency all the time.

You may need to have larger radiators, skirting heating or underfloor heating to provide enough heat at lower flow temperatures so it’s worth checking that your house is being comfortably warmed with the radiators you have before adjusting the flow temperature.

HOW DO I MAXIMISE MY SYSTEMS EFFICIENCY?

Many central heating systems still only have a boiler thermostat,

usually in a central location such as a hallway. When the hall

reaches the set temperature then the boiler assumes the whole

house is warm and turns the heating off. However, very few people

live in the hall, so now it is customary to have some form of control

in each room such as a Thermostatic Radiator Valve (TRV) or a

wall mounted thermostat.

Digital or Smart thermostats that can be programmed for time and

temperature (and can be wireless as well as wired) and are better

still as they control each room as required (so the bedrooms are

OFF during the day for example) minimising the time that the

boiler is on, and the total number of rooms heated.

There are hundreds of suppliers of suitable thermostats for central heating systems, and whilst really clever features such as a Phone App to program them, or a GPS locator that knows when you have left work and returning home is a great selling feature, in reality a clear and simple and easy to understand room thermostat is more likely to save you money in the long run.

Is My System Running Right?

HOW TO TELL THAT EVERYTHING IS TICKETY BOO...

When your boiler is serviced, your engineer will do a series of tests including of the flue gases, which indicate if the boiler is burning cleanly and thus efficiently. However, you may find that your radiators or skirting heating are not getting hot, and you may think this is because your boiler is faulty or needs replacing.

HANG ON! YOUR BOILER MIGHT BE JUST FINE...

MY RADIATORS AREN'T ALL GETTING HOT

If some radiators are getting warm and others not, chances are it’s trapped air and the problematic radiators need to be bled. More seriously it could be sludge in the pipework caused by the steel radiators rusting from the inside (skirting heating is usually made from aluminium so it won’t be rusting). This will require a flush to clean out the waste, and the system refilling with clean water and suitable rust inhibitor.

Skirting Heating is made from aluminium, so will not rust and sludge up your system

IS MY PIPE WORK PAST IT?

In really serious instances, the pipework itself may be past its sell by date (typically 40~50 years), and so replacing your boiler because your house is not heating up is not going to solve the problem.

Your heating engineer should be able to measure the pressure from and then the return to the boiler with all the radiators open and see if there is a significant pressure drop requiring remedial action.

Boiler Dropping Pressure?

WE SIMPLIFIED SOME OF THE MOST COMMON PROBLEMS,

Your system needs to be properly pressurised to work efficiently. This is

typically 1.5~ 2.2 bar on the boiler pressure gauge (usually indicated by the

green section on the gauge).

If your system continuously needs topping up (a boiler will usually go into

fault mode if the pressure drops below 0.5bar) then you may have a leak

somewhere on the system.

If you have a leak on a radiator or skirting heater, these are very easy to

find and remedy- usually it will be where the pipework connects onto the

radiator panel and simple to get at.

Leaks in pipework or underfloor heating buried in the floors or walls can be very destructive over time and so need to be addressed quickly to avoid more significant repair costs later. Specialist companies are available to trace leaks in the floors or walls

NO LEAKS? IT'S POSSIBLY YOUR EXPANSION VESSEL

The more likely is a faulty expansion vessel that relieves

and balances pressure in the system as the water is

heated and cooled.

The expansion vessel is usually inside the boiler or it is a

red or white 10~25Litre cylinder close to the boiler with a

car tyre type valve on the top.

If it has lost pressure and you have a traditional system,

then your pressure relief valve on your hot water cylinder

will constantly drip during the heating cycle (there is no

room in the expansion vessel to take up the change in

water volume) or the expansion vessel will make a solid

‘dull’ sound when tapped with a metal object (as it’s full

of water and not air).

In this case, to double check you can attempt to depress

the car tyre valve for a moment to see if any air (or

water escapes). If its air, chances are the problem is

elsewhere. If its water, you may need to repressurise or

replace the expansion vessel; either way its best done by

a plumber if you’re not familiar or have the right tools.

Are You in a Hard Water Area?

AVOID DAMAGING YOUR SYSTEM ARMED WITH THIS INFO,

It is common in areas with high levels of calcium carbonate dissolved into the water, to use a water filter or softener to reduce limescale and improve the taste. Under no circumstances should chemically softened water be plumbed into the central heating system. Whilst limescale can build up in appliances that are constantly being refilled (such as kettles, baths etc) the water in the central heating is a ‘closed’ system and apart from the occasional top up (see above) the calcium carbonate levels are static. As such limescale build up is minimal in closed loop systems especially if plastic pipe has been used. Introducing chemically softened water can damage boilers, heat exchangers, aluminium radiators etc. and should be avoided at all costs. Mechanical or centrifugal filters do not present such a hazard, but double check the suitability of your heating system to accept softened water. If in doubt, treat only the domestic potable water.

You're Ready!

SUMMARY

- All boilers should be A or A+ if fitted in the last 10 years

- Keep your boiler serviced every 2~3 years (every year if it’s a rented property)

- Ensure your system is filled with clean water and a suitable rust inhibitor

- Use individual room controls to reduce wasted energy

- If your system continuously loses pressure; get it checked!

- Avoid using chemical water softeners in central heating systems

DiscreteHeat can assist with your understanding of your central heating system, and provide the technical assistance to ensure a high performance end result.