B*llocks to Boilers?

It seems that the UK in it’s eagerness to blaze a trail in CO2 reduction, is about to implement the most stringent restrictions on new gas boilers and other Co2 generating equipment.

With home heating accounting for 18% of UK CO2 emissions

For as long as anyone can remember The UK has relied on fossil fuels like natural gas, oil and coal to power our homes, industry and transport.

Although these fuels have enabled the UK to develop both economically and technologically, time is running out due to the impact of climate change and the resultant changes in the worlds’ weather. North sea oil is depleting, the opportunity for shale fracking seems to have passed and other sources such as Russia and the Middle East make uneasy bed-fellows.

The Climate Change Act was passed by the UK government in 2008 as a 1st step in tackling the issue. The Act ensures that the UK’s carbon emissions are at least 80% lower than the 1990 baseline by 2050. The Act also gives the Secretary of State for Energy and Climate Change powers to introduce new measures to achieve these targets.

It’s not going to be easy, especially when you consider that there are a number of competing and apparently contradictory objectives set out by the Department of Business, Energy and Industrial Strategy (BEIS):

- Ensure a secure and robust energy supply

- Reduce energy bills or keep them as low as possible

- Encourage home improvements to reduce energy consumption

- Reduce carbon emissions cost-effectively at home

So there has to be big, long term changes to way we heat our homes, but with lower ongoing energy bills & minimal up-front costs.

The establishment of the Committee on Climate Change (CCC) directly followed the Climate Change Act, which is an independent advisory body which informs the government as to progess in reaching required carbon levels. This progress is reported to Parliament.

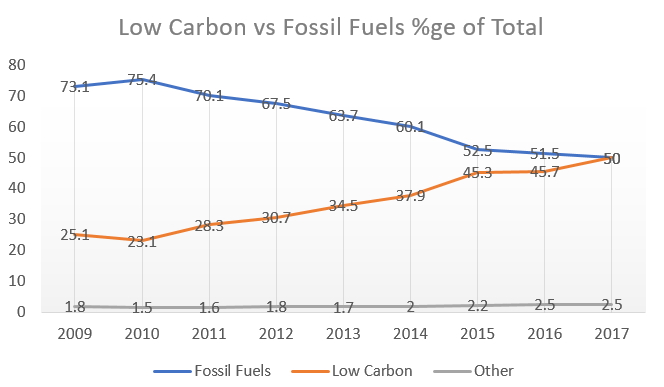

2017 was the first year that more electricity was generated from renewable sources than fossil fuels As a result 2017, UK emissions were more than 40% lower than 1990 levels with most of the reduction in carbon down to impressive progress in reducing emissions from electricity generation. The UK is currently forecasted to outperform the second (2013-17) and third (2018-22) carbon budgets. Currently the UK is unlikely to meet the fourth carbon budget which covers the period 2023-27. This is because the UK is falling behind in its progress in reducing the carbon created in heating our homes.

According to the committee on climate change (CCC):

In 2018 Legislation was passed to phase out inefficient gas boilers; this regulation known as ‘Boiler +’ requires that all new Combi boilers must have a minimum energy efficiency of 92%. In March 2019 it was stated that from 2025 it will be illegal to install gas boilers in new build homes & the UK government plans to almost completely phase out the gas network to power homes by 2050.

You can read more about the Boiler+ Requirements here: https://www.gov.uk/government/groups/heat-in-buildings

The report suggests that the most likely solution could very well be a hydrogen. Hydrogen only creates heat energy and water vapour when burned and so has zero CO2 emissions. Hydrogen is also very energy intensive as 1kg of hydrogen has the same amount of energy as 2.8kg of fuel oil.

It has been suggested that simply converting the Natural gas network to Hydrogen would be much more complicated than the switch from Town Gas in the 60’s; Hydrogen molecules are much smaller than methane and so leaks and losses would be higher. Similarly, it is unclear whether the existing gas boiler stock could be cost effectively converted, as it is not a simple conversion to run an existing boiler on hydrogen as it was to swap the burner jets in the conversion from town to natural gas.

The CCC report indicates that the better option would be to combine different renewable technologies such as heat pumps, solar, biofuels etc to provide an overall low-carbon heat network.

In particular, the CC report recommends that space heating could be provided by the existing gas boilers and DHW heating by direct electric supplied by renewable sources, as the overall lower cost solution. By retaining the gas boiler, it suggests, this would allow households to retain their existing pipework and radiators. However, heat pumps generally produce low grade heat in order to function most efficiently and these would be better suited to produce large volumes of domestic hot water at 40~50°C rather than the heating.

This 2-step solution seems to be superfluous – why not just upgrade the boiler and gas network to hydrogen and then both the space heating and DHW can be provided from one localised source? This would significantly increase the chances of hitting the 80% reduction target on time.

The Chief executive of the CCC, Chris Stark, said:

Converting the UK from gas to hydrogen boilers would be a monumental project and one that could not be carried out overnight. One problem is that hydrogen is highly flammable and therefore generally considered a hazard. Would new safety precautions be required or a re-evaluation of the risk undertaken? Would gas and hydrogen run on the same network, or would we have to carve out regions or sections for Hydrogen only?

Although hydrogen emits zero emissions when burnt, creating hydrogen is energy intensive and does produce carbon in the process . Carbon capture technology already exits on a small scale, but this would need to be built into the manufacturing process on a large scale. This is already done in the production of hydrogen for industrial or medial use using steam methane reformers, and then stored for reprocessing into other products and effectively ‘captured’.

Inevitably there would be a high degree of inertia to overcome and significant re-education of the installer network, as well as the inevitable scepticism of the wary consumer already disillusioned by other government energy saving initiatives on diesel & hybrid cars, and the fiasco that was the Green Deal.

- Public engagement on the future of the UK’s energy strategy. Clear and unambiguous information as to future policy.

- Kick start the process by committing to large scale creation and storage of hydrogen to encourage providers.

- Widespread publicity of successful pilot schemes to underscore the direction of travel, to a public currently in tune with climate concerns.

Heat pumps have long been touted as the future of home heating as they rely on the thermodynamic principle of the latent heat of evaporation to steal heat from the air (in the case of an air source heat pump) or earth (if a ground source heat pump). The concept has long been compared to a ‘fridge in reverse’ in that if you feel the air behind or below your fridge freezer you will experience the heat that has effectively been extracted from the food within.

By running on direct electricity, the holy grail of heat pump performance measure has been a COP (Co-efficient of Performance) of 4:1 in which 1 kw of electrical energy creates 4kw of heat energy. This arbitrary figure is really only to create a competitive advantage against alternative forms of heating other than gas, as gas is generally ¼ of the price of electricity per kwH. The COP benchmark of 4:1 for a heat pump is really only a way by which Heat Pump providers can make an argument for replacing a gas boiler as well as an oil, or direct electric heating system.

Some Air Source heat pump manufacturers are achieving a seasonally adjusted COP approaching 3.9 : 1. The seasonally adjusted figure is an average across a year which reflects the fact that heat pumps work more effectively in the warmer months than they do in the depths of winter; they do after all rely on the air around the fan unit to provide the extractable heat energy.

There are however some hurdles to overcome if heat pumps are to realistically become the go-to technology for home heating.

- They are more expensive to install and maintain. A result of relatively low volumes and fewer manufacturers as well as more moving parts operating at high pressures.

- The installer network is far smaller than that for gas boilers. Simply finding a suitably qualified and experienced engineer to install and/or repair a heat pump system is a challenge, especially in more rural, less densely populated areas.

- The emitters required are often larger and more complex to install than a standard panel radiator to compensate for the naturally lower water temperatures created by a heat pump (if it is to have any hope of approaching a COP of 4:1)

Whilst hurdles 1 & 2 might be considered the ‘Water Jump’ and ‘Canal Turn’ in racing parlance, the 3rd is definitely Bechers Brook. This is because whilst the issues of volume and availability can be solved by stimulating the market and legislation, providing a suitable emitter can present it’s own difficulties, especially in the 20+ million homes already built and on a gas boiler.

Underfloor heating (UFH) has often been partnered with heat pumps, especially on well insulated new build and on ground floors as the greater surface area works well at the lower flow temperatures provided. It still remains a niche retrofit solution due to the upheaval involved (all the furniture out and floors up for a start) especially in occupied or tenanted properties.

Oversized radiators are another option, but given that many modern properties are already struggling for useable wall and floor space, is it desirable to retrofit radiators up to twice the size of their boiler compatible predecessors?

Similarly fan assisted radiators will provide the necessary heat output at low input temperatures but will require a new electrical circuit to provide the power, increasing the final installed cost.

Skirting board heating is easier to retrofit than UFH, and can operate at the same lower flow temperatures as UFH, and is of course immune to variance in performance due to floor coverings or construction. Its low water content can help response times and controllability which improves somewhat the COP of the heat pump, and does not necessarily require any electrical controls, often connecting onto the existing radiator pipework.

Heat Pumps are growing in popularity, but still seem best applied in new build, off-gas projects where insulation levels are naturally very good and the oversized emitters required to allow them to perform properly can be installed from the get-go.

Less obvious is the retrofitting of heat pumps into existing properties with lower levels or even poor insulation, especially those already connected to, or with ready access to the gas network, which could go hydrogen in the medium term.

Coming up on the rails (there’s that racing analogy again) is direct electric heating in the form of panel heaters or radiant skirting board heating.

Until recently, direct electric heating was considered an anathema to low carbon construction and the drive to nett zero. This was because of the high reliance on fossil fuels to create the electrical energy in the 1st place, and the losses in transmission from power station to home (which roughly explains why electricity is around 4 x the price per KwH of gas).

However, the surge in renewable energy created from wind and solar has turned these assumptions on its head.

In the latest SAP 10 regulations (SAP being the Standard Assessment Procedure for the energy efficiency of houses) published by the BEIS, electricity has almost the same carbon footprint as natural gas.

Electricity 0.234 kg/KwH Gas: 0.203 kg/KwH a difference of only 10% in terms of a ‘penalty’.

What this means is that developers and housebuilders, who have to demonstrate compliance with SAP 10 in order to achieve planning permission and building regulations are re-appraising the use of direct electric heating; none more so in apartments and multi-residential developments.

The ease of installation of a direct electric heating system, and the lack of pipework, distribution manifolds, heat interface units and even combined heat and power plants (CHP) in the basement of high rise blocks, means a huge capital saving, even if they have to provide higher levels of insulation and other renewable technologies such as solar panels to fully comply.

Similarly, point-of-use water heaters to sinks and showers, means there is no storage space dedicated to DHW, and only the water used is heated.

Better insulation means that whilst direct electric heating remains approximately 4 x the price of gas per KwH, it is now 4 x ‘not much’.

For these reasons, many of the major housebuilders are reviewing their commitment to wet heating technology, and also because the forward trajectory of government policy is uncertain. We know there will always be a supply of electricity; we can’t say that for certain about gas, oil, hydrogen or heat pumps.

Solar can assist in reducing the properties reliance on the boiler by generating hot water either by solar thermal (heating water or fluids) or solar photovoltaic by absorbing sunlight through 2 disparate semi conductive materials (thus creating an electric potential difference and consequently voltage flow).

In either case, by generating energy right at the point of use, it is perhaps the most carbon neutral solution as it requires no energy consumed in distribution through pumping gas or hydrogen through pipes or through losses in electrical conversion over the national grid.

However, as it relies on daylight (and not exclusively direct sunlight) it is somewhat at the whims of the weather. Given that the highest demand for heating is during the winter months (it’s accepted that hot water usage is generally stable throughout the year) solar thermal and PV make a better provider of DHW demand than space heating. Solar PV has the advantage that it can be stored and/or diverted to various applications within a property; immersion heating for hot water, LED light, EV car charging etc, whilst solar thermal is dedicated to DHW demand.

As a result, its current thinking that solar can make a difference to stand alone properties due to the available roof space, but is less likely to make much of a difference to space heating demand, or in multi-unit developments such as apartments where roof space is limited relative to floor area.

Biomass boilers consume renewable fuels such a wood, wood pellets or similar in domestic scale projects. Whilst eligible for RHI grants (Renewable Heat Incentive) as the burning of such materials is only releasing the carbon that was captured during the growth of the biomass material, concerns have been raised about it’s effects on the environment in terms of the smoke and ash released.

Burning waste timber that would otherwise go to landfill seems a particular virtuous circle, but in reality to provide a steady source of on-demand combustible biomass material on anything like the scale required to significantly reduce our carbon footprint, it would have the perverse effect of requiring fleets of delivery waggons shuttling tonnes of wood or similar around the country.

As a result there are no plans to encourage a mass roll out of biomass boilers in urban areas.

Well, no to be honest.

The Government has a poor track record on these things as evidenced by the debacle over diesel cars, and now more recently hybrids – they have a propensity to pronounce on something, over estimate what’s deliverable and affordable and then back track as their own self imposed deadline approaches.

It’s clear that ‘something must be done’ and that decarbonising our economy and in particular our home heating is a ‘good thing’. However without some serious joined up thinking such as:

- Who’s going to fit all these heat pumps given that the number of MCS (Microgeneration Certification Scheme) registered installers has dropped like a stone?

- How are we going to provide all the electricity needed to drive the heat pumps never mind the electric vehicles needed (by 2035 according to this weeks news)?

- If Hydrogen really is the fuel of the future, who’s responsibility is it to kick start the hydrogen manufacturing revolution if there’s no current demand?

- Given the age and insulation levels of much of the UK housing stock does adding expensive renewable technology such as heat pumps to a leaky, draughty buildings even make financial sense; surely reducing the heat load via remediation is the sensible 1st step?

- Now the UK has left the EU, would reducing the VAT rate to zero on proven insulation technologies such as double/triple glazing, loft, cavity and wall insulation not provide a Green kick start to any energy strategy?

If the Government is serious about phasing out Gas boilers by 2030 or even 2035 (any suggestion it’s going to be 2025 is ridiculous) then it really needs to get it’s ducks in a row. A clear and coherent strategy will require flexibility as well as clarity; a reliance on one measure is likely to prove unworkable.

There is no one size fits all. The reality is that a mixture of technologies; hydrogen, heat pumps, solar, bio mass and yes, Boilers will be the only, and sensible way of achieving Nett Zero by 2020.

So not so much B*ollocks to Boilers, or even Bye Bye boilers, more like au revoir, auf wiedersehen, arrivederci!

You can read more here: Telegraph - homeowners could be forced replace gas boilers